Pride in Workmanship

It is NEK’s goal to support our customer’s success by providing quality products delivered on time and competitively priced.

It is NEK’s goal to support our customer’s success by providing quality products delivered on time and competitively priced.

It is NEK’s goal to support our customer’s success by providing quality products delivered on time and competitively priced.

Electronic Assemblies Manufacturer with over 35 Years Experience, ISO 9001:2015 Registration, and US and ITAR Licensed Offshore Factories

New England Keyboard, Inc. (NEK) is an engineering and design company specializing in the design and manufacture of custom keyboards, keypads, and membrane switch keyboards, including custom electronics and enclosures. In addition to our data entry products, we offer a large variety of custom components including: resistive and capacitive type touch screens, Kapton® cables, bare rigid-flex and flex PCB assemblies, military grade LCDs, cast metal components, and in-mold decorated (IMD) components, to name but a few.

NEK is an ITAR registered U.S. manufacturer with on-staff Electrical, Material, Mechanical, and Quality Engineers. At our factory in Fitchburg, Massachusetts, we have screen printing, die cutting, laser cutting, PCB wave solder and SMT, cable assembly, and adhesive membrane switch assembly capabilities. Using our U.S. facilities and/or our 34 ITAR licensed factories in Taiwan, we can custom design and manufacture any of the following products and components.

Rugged, reliable, and designed to meet the most demanding applications and environments.

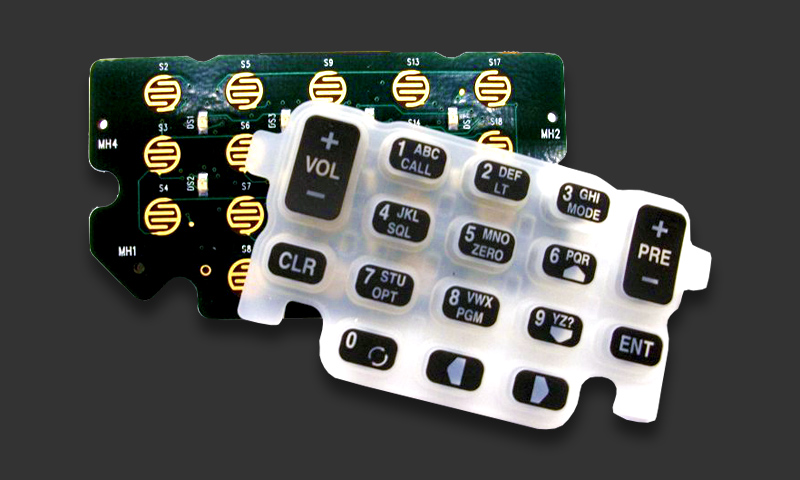

Rugged, short stroke, custom silicone rubber keypads offer substantial design flexibility.

We design and manufacture terminals, key panels, stand-alone products, and higher level subassemblies.

ITAR registered and manufactured products used by the Military or in very harsh environments.

Custom flat panel membrane switches, with special solvent resistant textured overlays, will stand up to the harshest environments.

Helps reduce costs, weight, meet dynamic flexing requirements, and eliminate connectors, thereby increasing reliability and repeatability.

Rugged Liquid Crystal Displays (LCDs) and Liquid Crystal Modules (LCMs) for a variety of demanding applications.

Variety of casting methods and materials to guarantee you the most cost effective approach based on individual applications.

Our standard touch panels are smart modules with integrated LCM displays and touch screens.

Specialized to design your component to take advantage of plastic material’s inherent strengths and accommodate their weaknesses.